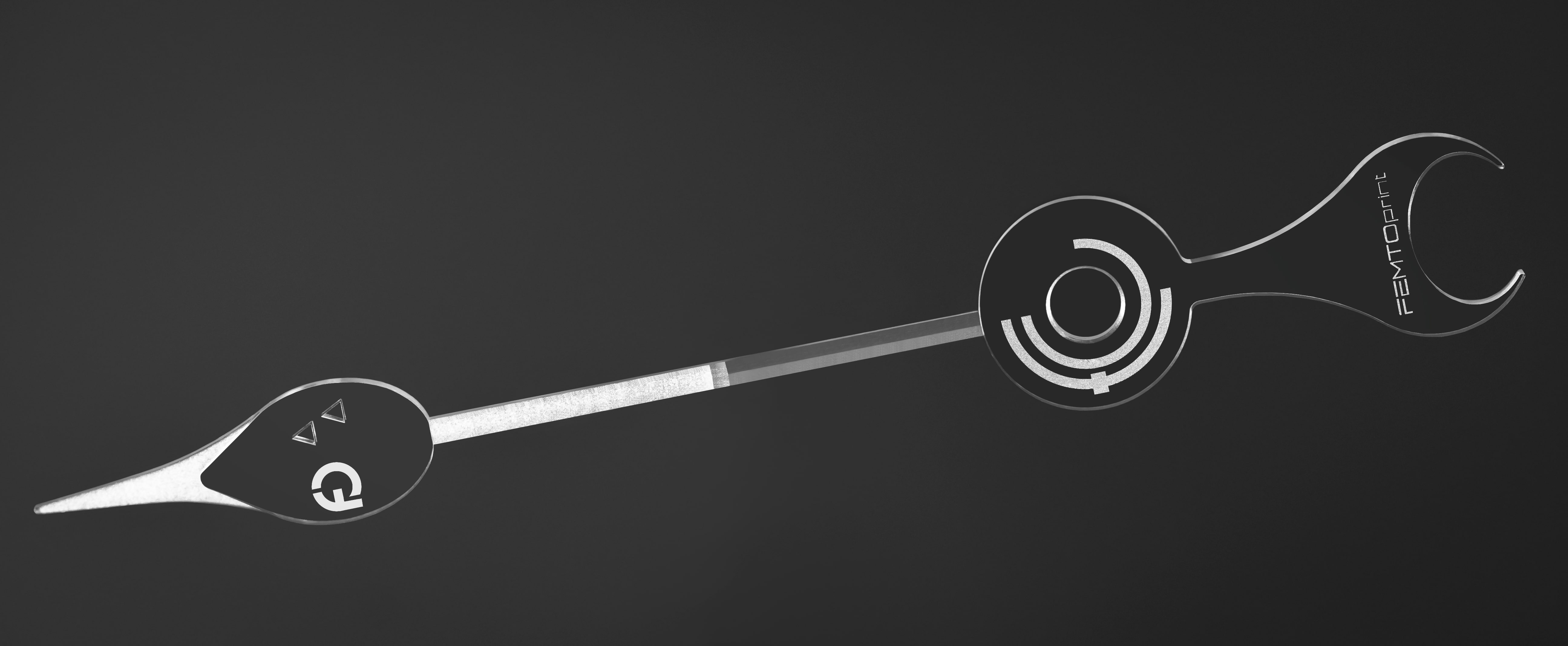

Reinventing Watch Hands with Fused Silica and BF33.

At FEMTOPRINT, we bring this tradition into a new era with high-precision glass watch hands manufactured in fused silica and BF33 through advanced laser micromachining. Our innovation combines Swiss craftsmanship with cutting-edge microfabrication, delivering hands that are lighter and aesthetically unique.

“Dauphine”, “Stick”, “Leaf”, “Breguet”: watch hands come in many shapes and sizes. More than functional indicators of time, they are a visual signature that gives life and identity to every timepiece.

At FEMTOPRINT, we bring this tradition into a new era with high-precision glass watch hands manufactured in fused silica and BF33 through advanced laser micromachining. Our innovation combines Swiss craftsmanship with cutting-edge microfabrication, delivering hands that are lighter and aesthetically unique.

Key Benefits of FEMTOPRINT Glass Hands

Lightweight Performance for Greater Precision

Material choice is critical in watchmaking. Compared to sapphire, fused silica is almost twice as light at equal volume, and nearly four times lighter than brass—the conventional material for hands. This reduction in weight means less energy consumption, translating into a longer power reserve and improved accuracy in mechanical movements. With lighter hands, the heart of the watch works more efficiently, ensuring that precision lasts longer.

Transparency Meets Design Freedom

Fused silica and BF33 enable transparent and polished hands, bringing a modern visual identity to traditional craftsmanship. Our proprietary process allows true 3D shapes, intricate engravings, luminescent pigments, and optical effects—design features impossible with conventional metals.

Swiss Quality, Unlimited Creativity

Each FEMTOPRINT hand is crafted with functional surface treatments that ensure optimal contrast and legibility. Our microfabrication technology eliminates tooling limitations, offering complete creative freedom—from semi-transparent finishes to sculpted chamfers that harmonize with movements.

Looking to elevate your next timepiece with innovative glass hands?

Connect with our team at FEMTOPRINT for tailored solutions, rapid prototyping, or technical consultations.

Certified Reliability – ISO 9001:2015 and RoHS compliant

Certified Reliability – ISO 9001:2015 and RoHS compliant

Vertically integrated solutions providing unique glass 3D components, functionalized and ready to be integrated into finished products.

Vertically integrated solutions providing unique glass 3D components, functionalized and ready to be integrated into finished products.

Swiss Made, thus supporting our clients with 100% Swiss-based manufacturing, from prototyping to volume production.

Swiss Made, thus supporting our clients with 100% Swiss-based manufacturing, from prototyping to volume production.

10+ years of engineering expertise in helping watchmakers to unveil true innovative timepieces.

10+ years of engineering expertise in helping watchmakers to unveil true innovative timepieces.

High-quality and high-precision components for the most demanding applications.

High-quality and high-precision components for the most demanding applications.