In recent years, 3D printing has attracted increasing attention in many industries. From bioprinting of living organs to engine and airplane components, a variety of 3D printing techniques are already in use today, mainly differentiated by the additive or subtractive manufacturing approach. But what’s the application potentiality in the med-tech industry with regards to 3D printing at micro-scale? And how innovative three-dimensional thinking can tackle human diseases such as the retinal vein occlusion (RVO) and create transformative products?

FEMTOPRINT, in collaboration with Galatea Lab, Instant Lab (EPFL, Switzerland), and the Jules-Gonin ophthalmic hospital (Lausanne, Switzerland), recently joined their forces into a consortium to realize a challenging, glassbased compliant puncture tool for retinal vein occlusion (RVO), a common retinal vascular disorder causing severe loss of vision and affecting around 16 million patients worldwide over fifty years old.

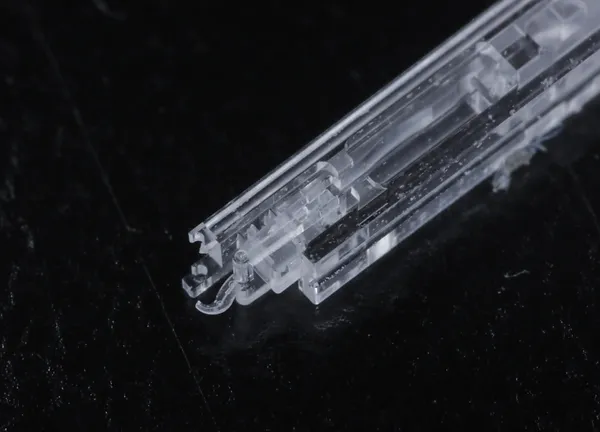

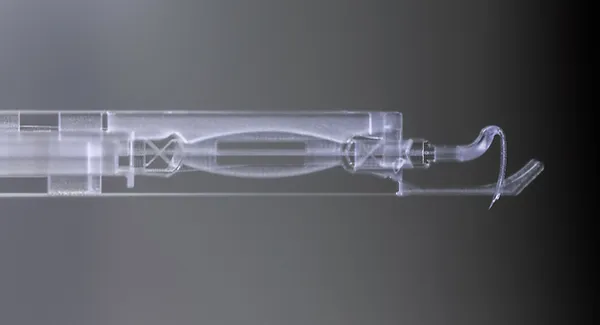

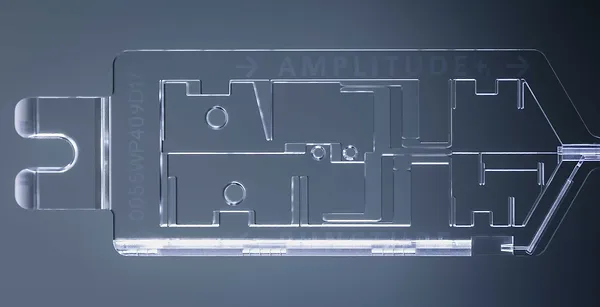

The developing group conceived, manufactured and tested a passive compliant tool for retinal vein cannulation (RVC) that relies on a buckling mechanical principle to safely and precisely cannulate veins in eye surgery, independent of the actuation input. This has been possible by combining the advanced manufacturing capabilities of the FEMTOPRINT technology with the glass properties, like robustness and favorable elasticity, transparency and biocompatibility.

Experiments conducted to-date have been very promising. The stability programming of the double pinned bistable beam gives control over puncture force and stroke. The puncturing method has then been validated by FEM simulations and experimental measurements, demonstrating several advantages for both the patient and the surgeon. In an experimental trial, the tool successfully cannulated pig eye retinal veins. In its final configuration, the surgical tool can be used in either stand-alone mode or mounted onto a robotic system.