We all know that glass has unique capabilities: it is transparent, corrosion-resistant, thermally stable, electrically insulating, scratch- and abrasion-resistant, elastic and biocompatible. But who imagined using glass that combines all these properties with its tribological behavior to make complete three-dimensional watch mechanisms, integrating precision, aesthetics, and multi-functionalities? Probably none before FEMTOPRINT®’s 3D printing era.

Ten years after the first InnoVision timepiece, the Swiss watch manufacturer Ulysse Nardin presented a second version of this concept watch at the Geneva Watch Exhibition last January (SIHH 2017). The InnoVision2 is an exceptional timepiece that is pushing innovation boundaries. Ulysse Nardin chose FEMTOPRINT and its versatile laser platform to design, shape, and create real sculptures as well as multi-functional components out of glass for this watch.

FEMTOPRINT SA’s 3D printing platform is able to produce challenging, monolithic 3D shapes at sub-micron resolution with high-precision, repeatability, and optical surface quality, thanks to its versatility and the inexpensive configuration. This technology is an affordable and transformative solution to leading-edge markets like the watch industry.

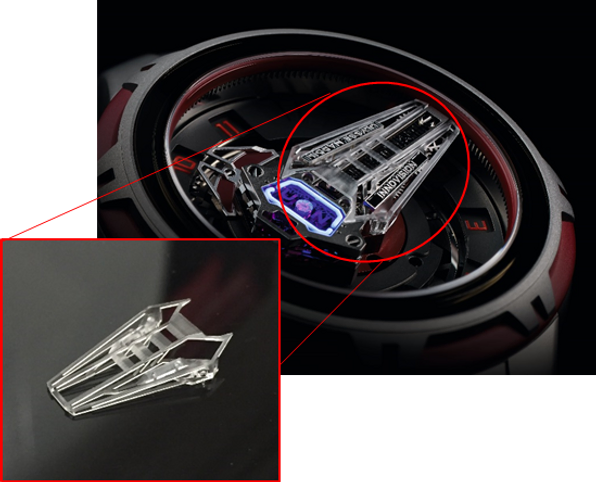

InnoVision2 is an extreme example of how progressive attitudes and advanced laser technologies can work together to create an innovative product, on which creativity pictured a fine 3D transparent minute hand (FIGURE 1), a monolithic component with integrated balance shock protection, microchannels for a distinct illumination, and their own brand engraved in the bulk. At the same time, accuracy on the critical dimensions, material properties, and surface quality were the key.

The InnoVision2 watch features unique 3D glass sculptures - nothing like anything seen before. Each component of this timepiece boasts an innovation, and the FEMTOPRINT® platform allowed conceiving the new transparent functional components, which are precise and show an amazing combination in a monolith of fluidics, mechanics, and low friction between moving parts, high surface quality and beauty. The integration of these new functionalities makes this watch a revolution in horology.

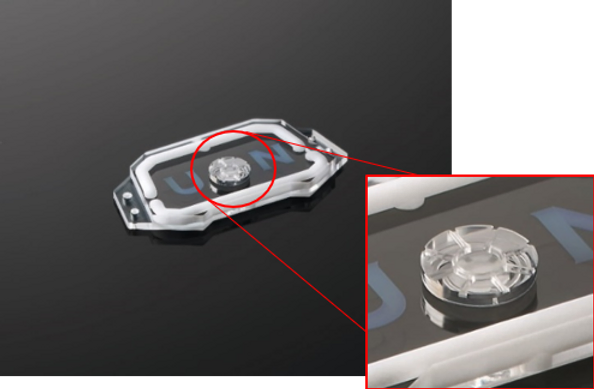

Among the 10 innovations brought to this timepiece, a new concept of light and the use of glass emerge. The watch is not as fragile as you would think. Actually, its revolutionary balance wheel bridge even has an integrated formulated shock resistance system, produced in one single piece, without masks, ablation, assembling, or other traditional manufacturing processes (FIGURE 2).

Also, thanks to the channels produced in the glass balance wheel bridge (also in a monolith) with the FEMTOPRINT® platform, Ulysse Nardin was able to introduce light, filling them with photo-luminescent pigments. The light sharpens the brand letters that are printed in the glass with the same 3D printing platform as change of density and refractive index.

Another innovation refers to the watch minute hand, which is sculpted in glass using the laser platform. The intricacy that can be achieved in the manufacturing process is in the 1-3um range, with high aspect ratio (more than 1:500, depending on the material) and accuracy on the trajectory of +1um, freedom in the 3D shape, and low roughness, ensuring the creation of challenging 3D micro-devices. The delicate glass hand is able to bear extreme shocks. As mentioned, glass is not only transparent, stable and dielectric, but also resistant and flexible. Furthermore, here the spectacular hand has been placed on thin metal backing.

This successful experience confirms that innovation is just a matter of creativity.