Over the last decade, biological and chemical research has moved in the direction of fast and highly sensitive molecular analysis. From this perspective, micro-mechanical resonators offer a promising solution, providing real-time, high -resolution detection of low masses down to a single biomolecule. Working in a dynamic configuration, the resonator oscillates with a characteristic resonance frequency, proportional to the resonator mass. The addition of new mass to the resonator, for example from cells or bacteria, causes a shift in frequency directly proportional to the added mass.

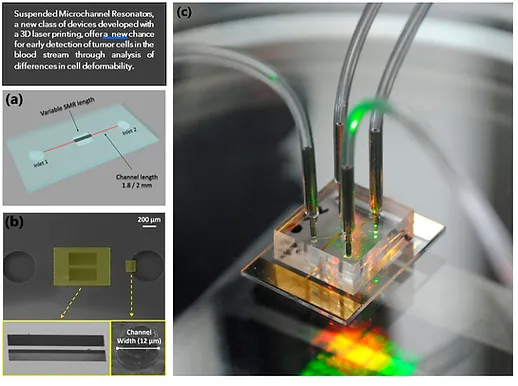

A new class of sensors based on these resonators, called Suspended Microchannel Resonators (SMRs), consist of a microfluidic channel embedded in a vibrating cantilever under vacuum. SMRs allow high-resolution measurement of density, viscosity, and specific gravity of fluids, as well as simultaneous detection of both position and velocity of target analytes through monitoring of multiple resonance frequencies. The ability to monitor small variations directly in a liquid environment has brought these resonators to the forefront of biosensing technology, representing a valid alternative to more traditional biosensing approaches.

Indeed, these capabilities offer an extremely attractive solution for integration into Lab-on-a-chip devices for clinical analysis and new “flow through” measurements, providing for example, early discrimination of tumor cells in the blood stream through detection of differences in cell deformability. This is possible by introducing a small bottleneck inside the SMR and monitoring the transition time of healthy and malignant cells[i].

Another promising application is the prediction of therapeutic efficacy using ex-vivo cells through investigation of different therapeutic treatments or dosage. SMRs can be used to select the most effective treatment by measuring the mass accumulation rate (MAR), a technique often applied to tumor cells[ii].

The widespread use of SMRs has been limited by the traditional fabrication processes, which involves photolithography and etching, using materials such as silicon, silicon oxide and silicon nitride. Although this fabrication process is effective, it is often challenging, time-consuming and expensive, requiring long development cycles to ensure optimization. Additionally, the multi-step nature of the process requires a cleanroom environment to ensure successful fabrication of functional, defect-free devices.

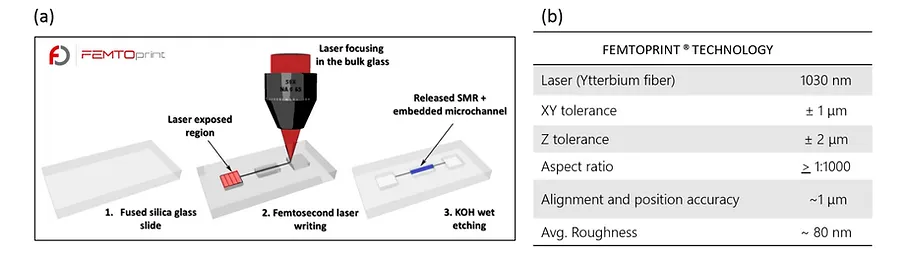

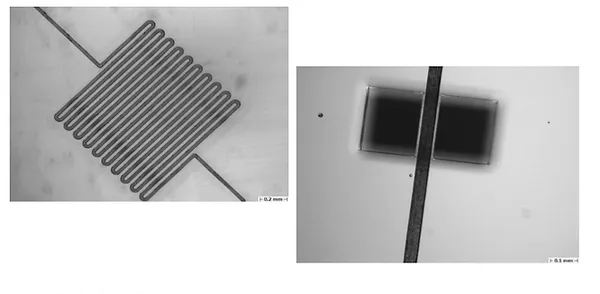

Recent improvements in femtosecond laser micromachining have enabled fabrication of micro-scale devices in glass, combining structural features with optical and micromechanical functionalities. Using a laser 3D printing technique based on this technology, a transparent SMR made entirely of glass was developed in a collaboration between the Applied Science and Technology Department, Politecnico of Turin, and FEMTOPRINT SA, a microtechnology based company (Figure 2).

The FEMTOPRINT technology enabled fast production of a monolithic SMR without residual stress and assembly error, which is a common issue in multi-step processes that compromises the mechanical performance of the sensor. The high resolution of the FEMTOPRINT technology allowed to reach geometrical tolerances of around 2 µm, with high repeatability & alignment precision < 1 µm. This is fundamental to guarantee a proper fabrication and mechanical behavior of the SMR, where small misalignment between the beam structure and the internal channels both in XY and Z may result in a wrong mechanical response of the system or in the worst case in a defective SMR. In fact, misalignment larger than 5um may cause the rupture of the sidewalls of the buried channel causing the destruction of the SMR.

Furthermore, a monomeric fabrication of a SMR in glass avoided the use of dissimilar materials, which would result in degradation of quality factors. Finally, the inherent transparency of glass allowed a more accurate quality control of the buried structures after fabrication, and the direct observation of cell growth or movements within the microfluidic channels during operation.

Besides third dimension, geometrical accuracy and surface quality, the integration of microfluidic, optical and mechanical functionalities in a glass monolith is certainly a game-changer for novel microsystem manufacturing, increasing significantly device performances and at the same time, to allow miniaturization, avoidance of complex alignment tasks and costly assembly steps.

The maskless, cleanroom-free and direct-writing process enables fast turnaround cycles of prototyping, increasing testing possibilities, design optimizations, and reducing go-to-market time, without needing large capital investments. At volumes production, the wafer-level and batch processing approach are supporting high throughput and process repeatability.

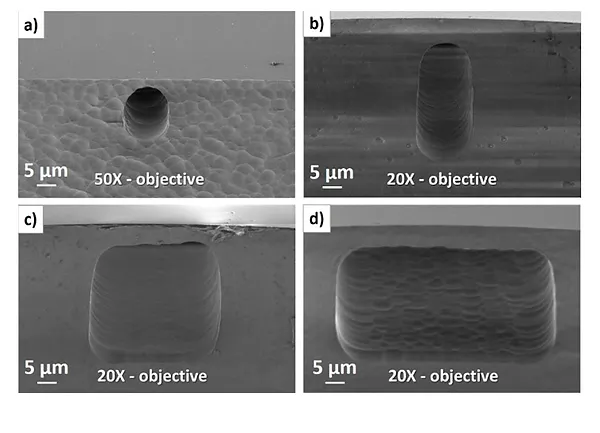

To test the FEMTOPRINT® technology for the fabrication of the SMR, a clamped beam design was chosen. Different dimensions were tested for beam length (250 to 1000 μm), width (50-75 μm), and embedded channel dimension (10-30-55 μm).

The channel shape was strongly dependent on the laser interaction volume, as shown in the SEM images (Figure4).

The resonance properties of the fabricated SMR were accurately characterized in terms of frequency, quality factor, and Allan deviation, factors which are useful for evaluation of the mass and density responsivity, as well as the minimum detectable mass (Figure 5).

Testing revealed that these monolithic glass SMRs could differentiate liquids of varying mass density down to a resolution of 1.04x10−3 kg/m3, a result comparable to the state-of-the-art silicon-based SMRs, while outperforming commercial micro-capillary glass resonators.

The effective biosensing capability of the SMR was demonstrated by evaluating the microbial load in aqueous solutions containing different concentrations of P. fluorescens. This bacterium was selected as the closest relative to the pathogenic P. aeruginosa, frequently responsible for multi-drug resistance in nosocomial infections. In this case, the glass SMR could distinguish different sample dilutions with high confidence and repeatability, resulting in a detection limit of around 60 picograms, or approximately 150 bacteria (Figure 6).

The FEMTOPRINT® technology is based on laser direct pattern in transparent materials, followed by selective wet etching. By exposing materials such as fused silica and borosilicate glass to precise and sub-micron focalized light voxel, the highly selective etchant removes the densified material, leaving intact the unexposed region.

The FEMTOPRINT® microfabrication technology, ISO 13485:2016 certified, finds its role as an innovative and unique industrialized platform for the manufacturing of advanced biomedical devices, covering the full value chain of a product, from R&D, rapid prototyping, pre-series and industrial volumes production.

A myriad of medical applications:

[1] Shaw Bagnall et al., “Deformability-based cell selection with downstream immunofluorescence analysis”, Integrative Biology 2016, 8: 654–664.

[1] Cetin et al., “Determining therapeutic susceptibility in multiple myeloma by single-cell mass accumulation”, Nature Communications 2017, 8: 1613.