Engineering Precision Meets Aesthetic Brilliance

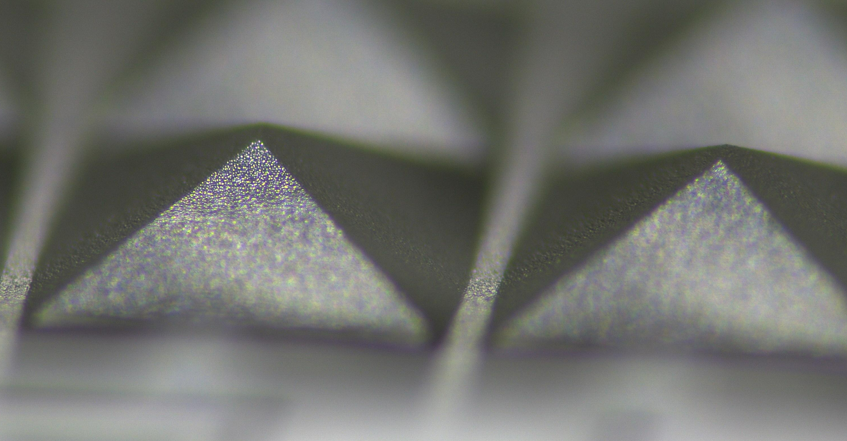

In the evolution of skeletonized watch design, glass movement bridges are transforming how mechanical beauty is revealed. At FEMTOPRINT, we manufacture high-precision glass bridges using state-of-the-art 3D laser microfabrication, delivering components that enhance both movement visibility and mechanical performance.

Designed for luxury timepieces, our fused silica bridges offer the perfect balance between sleek aesthetics and structural integrity. With micron-level accuracy and outstanding surface quality, they provide a modern, transparent platform that lets the inner workings of a watch become part of its visual identity.

Mechanical Strength with a Transparent Soul

While glass may evoke fragility, FEMTOPRINT’s glass components are engineered for strength and resilience. Our glass bridges maintain the rigidity and precision necessary to ensure flawless gear train alignment, making them fully compatible with high-end mechanical movements.

Each bridge undergoes specialized treatments to achieve:

These features guarantee long-term reliability — even in the most demanding environments.

Unleashing Design Freedom for Watchmakers

Whether you’re designing a skeletonized masterpiece or adding a modern twist to a classic caliber, our custom glass bridges bring a unique visual experience to your movement. Their transparent form allows more light and depth to reach the dial, creating a sense of openness and complexity that enhances perceived value.

Our wafer-level production platform ensures scalability, whether you're crafting limited editions or planning large production runs. Fully designed and fabricated in Switzerland, our bridges meet the highest expectations in the industry.

Key Benefits:

Want to explore how glass bridges can elevate your next movement architecture?

Connect with our specialists at FEMTOPRINT for personalized support and prototyping.